|

|

|

|

| Yizheng manufacturing base | Yangzhou manufacturing base | ||

|

|

|

|

| Ra0.4 Polishing of the reactor inner cylinder and rotating disc. Grade 0.4 |

Disk reactor spec:φ2400 × 14+3 25t

Material:S30408、S30408+Q345R

|

Esterification reactor hot-state vacuum test | |

|

|

|

|

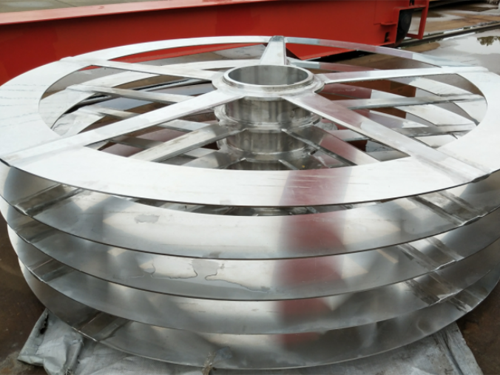

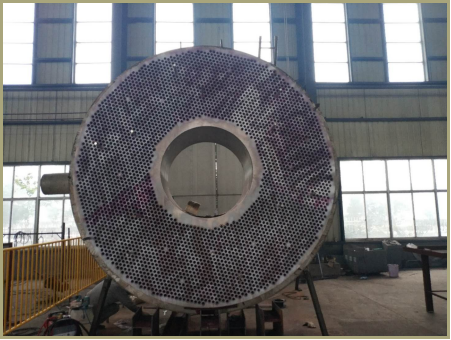

| The esterification reactor's heat exchange components include a total of 3,700 heat exchange tubes. After the initial passivation welding is completed and a pressure test confirms zero leak points, the surface is then covered. The components then undergo 100% PT inspection. |

3D model of esterification reactor

|

DN4000 Esterification reactor

|

|

|

|

|

|

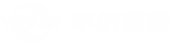

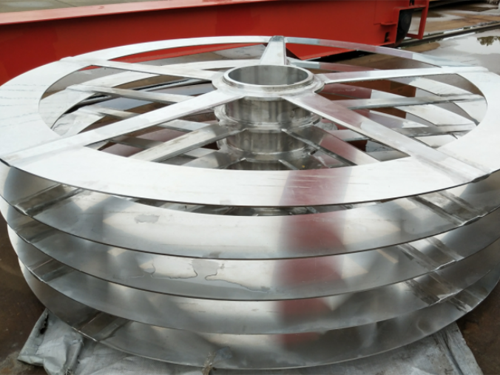

| Assembly of the rotating disk in a disk reactor | Preparation before shipment | Dynamic balance test of the rotating disk | |

|

|

||

|

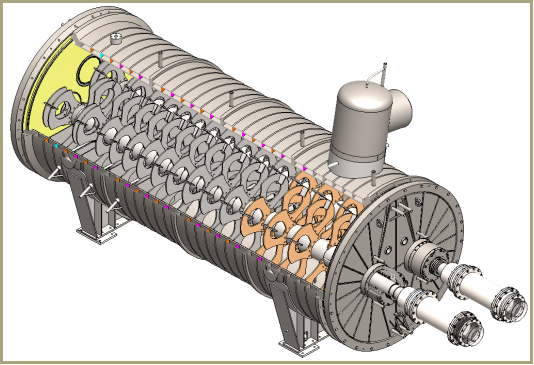

3D model of rotating disk

|

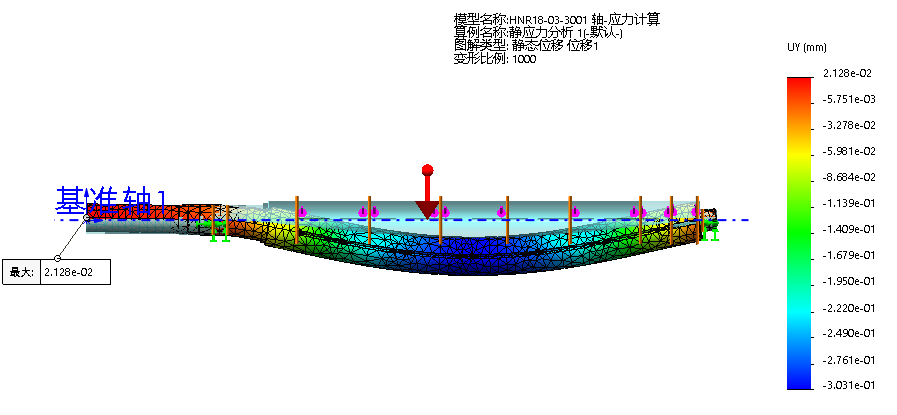

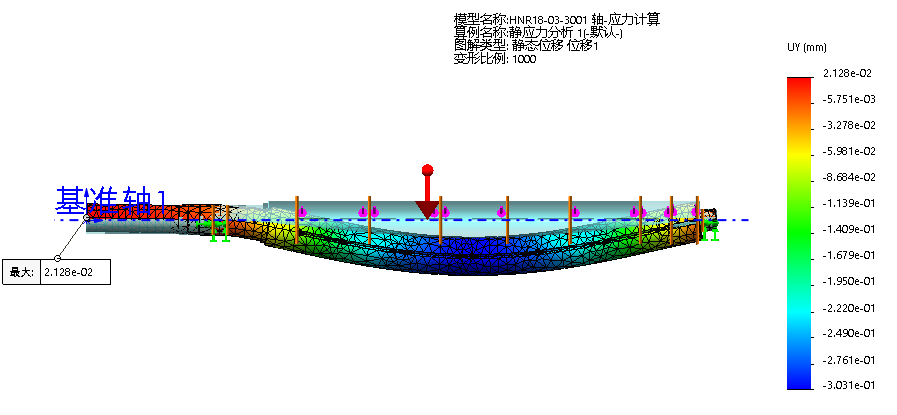

Finite Element Analysis of the Spindle

|

||

|

|

|

|

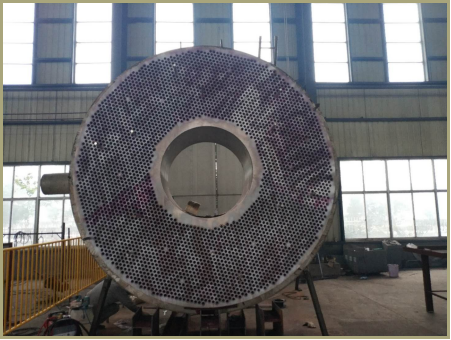

| Preparation before shipment of the parallel bi-axial reactor | Manufacturing process of the shell for the parallel twin-shaft reactor | ||

|

|

||

|

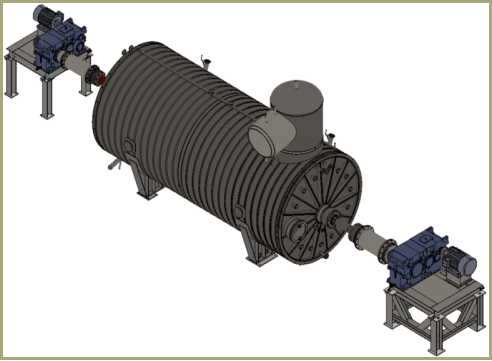

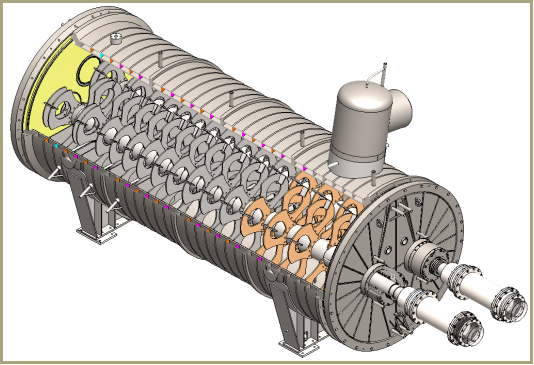

3D Model of parallel twin-shaft reactor

|

Installation and inspection of discs in parallel twin-shaft reactor | Manufacturing process of the shaft system in parallel twin-shaft reactor | |

|

|

||

|

Capable of conducting cold and hot-state vacuum tests

Capable of performing hot-state shock tests on critical equipment

Equipped with high-sensitivity detection methods such as ammonia leak detection and helium leak detection

|

|||

|

|

|

|

|

Loading and shipping of the main reactor for the Hainan Yisheng multi-functional polyester project

Integrated design and manufacturingDimensions: Φ4700 × 47000 mm, Weight: 135 tons Transported in three sections by road to the owner's site in Yangpu, Hainan. |

|||

|

|

|

|

| Main reactor for the Yisheng Dalian Multi-functional Polyester Project Specifications: Φ4500 × 47000 mm × 14, Weight: 126 tons Material: S30408 |

|||

|

|

|

|

| Yizheng manufacturing base | Yangzhou manufacturing base | ||

|

|

|

|

| Ra0.4 Polishing of the reactor inner cylinder and rotating disc. Grade 0.4 |

Disk reactor spec:φ2400 × 14+3 25t

Material:S30408、S30408+Q345R

|

Esterification reactor hot-state vacuum test | |

|

|

|

|

| The esterification reactor's heat exchange components include a total of 3,700 heat exchange tubes. After the initial passivation welding is completed and a pressure test confirms zero leak points, the surface is then covered. The components then undergo 100% PT inspection. |

3D model of esterification reactor

|

DN4000 Esterification reactor

|

|

|

|

|

|

| Assembly of the rotating disk in a disk reactor | Preparation before shipment | Dynamic balance test of the rotating disk | |

|

|

||

|

3D model of rotating disk

|

Finite Element Analysis of the Spindle

|

||

|

|

|

|

| Preparation before shipment of the parallel bi-axial reactor | Manufacturing process of the shell for the parallel twin-shaft reactor | ||

|

|

||

|

3D Model of parallel twin-shaft reactor

|

Installation and inspection of discs in parallel twin-shaft reactor | Manufacturing process of the shaft system in parallel twin-shaft reactor | |

|

|

||

|

Capable of conducting cold and hot-state vacuum tests

Capable of performing hot-state shock tests on critical equipment

Equipped with high-sensitivity detection methods such as ammonia leak detection and helium leak detection

|

|||

|

|

|

|

|

Loading and shipping of the main reactor for the Hainan Yisheng multi-functional polyester project

Integrated design and manufacturingDimensions: Φ4700 × 47000 mm, Weight: 135 tons Transported in three sections by road to the owner's site in Yangpu, Hainan. |

|||

|

|

|

|

| Main reactor for the Yisheng Dalian Multi-functional Polyester Project Specifications: Φ4500 × 47000 mm × 14, Weight: 126 tons Material: S30408 |

|||

Keywords

Equipment Manufacturing

The Manufacturing Division is responsible for the equipment manufacturing and R&D. With a total plant area of 20,000 square meters, it is the corner stone of Winner’s general contracting and EPC projects. It holds a Class D pressure vessel design and manufacturing license, and features a professional design team and an advanced pressure vessel design system. It also has comprehensive testing capabilities. Its business covers chemical, chemical fiber, and environmental protection. It specializes in manufacturing equipment made from special materials such as duplex steel, titanium alloy, Hastelloy, and Inconel625. Leveraging the shipping capabilities of the Yangtze River wharf, it can efficiently transport large-scale integrated equipment.

Contact Us

Classification